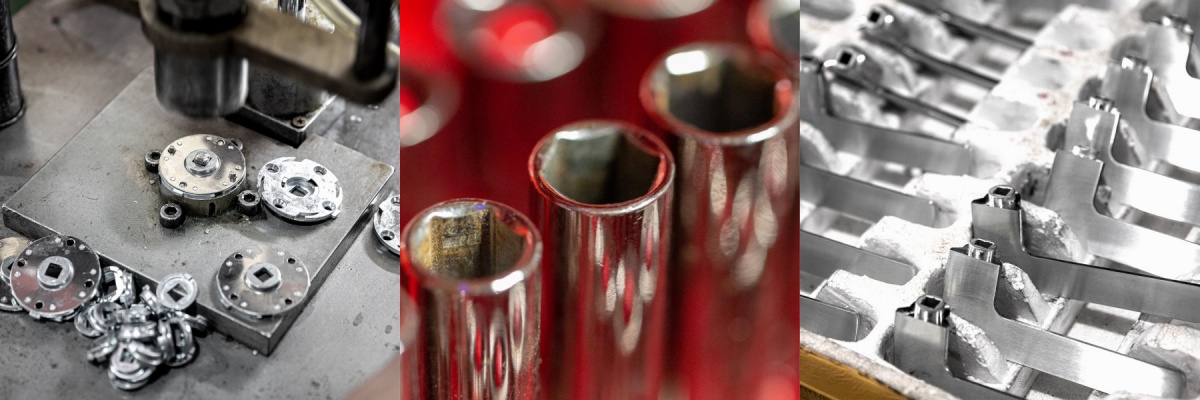

I-Die Casting

Inqubo ye-die casting ukucindezela insimbi encibilikisiwe ibe isikhunta ngaphansi kwengcindezi ephezulu ukuze kwakheke izimo ezihlukahlukene eziyinkimbinkimbi zezingxenye zehadiwe yomnyango. Le nqubo idinga ukuqedwa ngesikhathi esifushane kakhulu ukuvimbela insimbi ukuthi ingapholi futhi iqine. Ngemuva kokuthi insimbi ewuketshezi ifakwe esikhunjeni, idinga ukupholisa futhi iqiniswe. Inqubo yokupholisa ngokuvamile iqedwa phakathi kwemizuzwana embalwa kuya emaminithini ambalwa, kuye ngosayizi nokuma kwengxenye. Ngemuva kokupholisa, ingxenye izokhishwa esikhunjeni futhi icutshungulwe kamuva.

Ukwenza imishini

Izikhala kanye nama-die castings akhishiwe ngokuvamile adinga izinqubo ezithile zangemva kokucubungula, njengokuyikhipha, ukwelashwa kwendawo, ukukhanda imishini (ukubhoboza, ukucofa), njll. Lezi zinqubo zingathuthukisa ikhwalithi ephezulu kanye nokunemba kobukhulu bezingxenye ukuze kuhlangatshezwane nezidingo zokuklama.

I-CNC (Computer Numerical Control)

Inqubo ye-CNC isebenzisa izinhlelo zekhompiyutha ukulawula ukunyakaza nokusebenza kwamathuluzi omshini, futhi ingaqedela ngokuphumelelayo nangokunembile ukusika okuhlukahlukene, ukugaya, ukujika, ukubhoboza kanye neminye imisebenzi yokucubungula izingxenye ze-hardware zomnyango.

Amathuluzi omshini we-CNC angasebenza ngokuqhubekayo ngaphandle kokungenelela komuntu, athuthukise kakhulu ukusebenza kahle kokukhiqiza. Isikhathi sokucubungula sezingxenye eziyinkimbinkimbi sifinyezwa kakhulu, futhi umjikelezo wokukhiqiza uyancipha kakhulu.

Ngokushintsha izinhlelo namathuluzi, amathuluzi omshini we-CNC angakwazi ukuzivumelanisa ngokushesha nezidingo zokucubungula zezingxenye ezihlukene. Lokhu kuvumelana nezimo kwenza inqubo ye-CNC ifanele iqoqo elincane, amamodeli okukhiqiza enziwe ngokwezifiso amakhasimende.

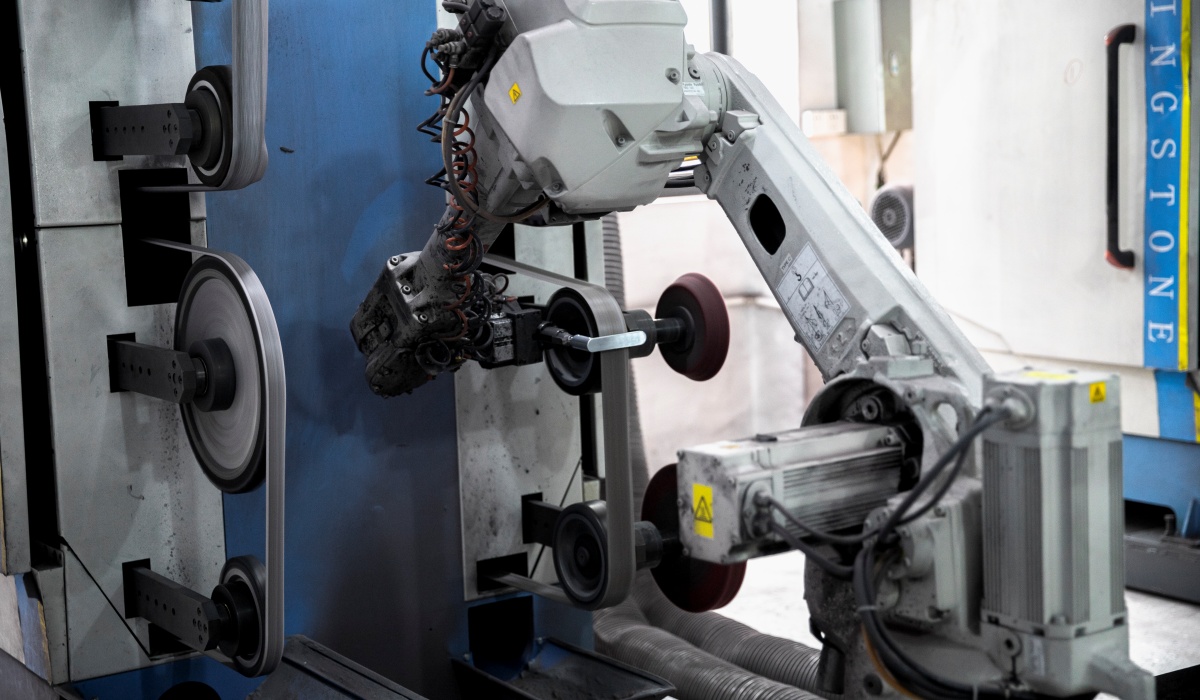

Ukupholisha

Ukupholisha kubalulekile njalo. Sinemishini yethu yokupholisha enabasebenzi abanolwazi ababalelwa ku-15. Okokuqala, sisebenzisa amabhande abrasive (okusanhlamvu okukhulu) okumahhadlahhadla ukuze apholishe “amaflashi” kanye “nezimpawu zesango”. Okwesibili, sisebenzisa amabhande abrasive amahle (okusanhlamvu okuncane) ukupholisha izimo. Ekugcineni sisebenzisa isondo likakotini ukupholisha indawo ecwebezelayo. Ngale ndlela, i-electroplating ngeke ibe namabhamuza omoya namagagasi.

Inqubo yokwelapha ebusweni: i-electroplating/spray paint/anodization

Ngemuva kokuthi ukungcola okungaphezulu komkhiqizo we-hardware kuphathwe, sekuyisikhathi sokwengeza umbala. Le nqubo ibizwa ngokuthi "i-electroplating" futhi umkhiqizo oye wabhekana nale nqubo ubizwa ngokuthi izingxenye ze-electroplated.

Umhlangano

Inhlanganisela yesibambo nesisekelo: Hlanganisa ingxenye yesibambo nesisekelo ngezikulufu noma amabhakede, futhi uqinisekise ukuthi ukuxhumana phakathi kwengxenye ngayinye kuqinile futhi akuxegi.

Ukuhlolwa okusebenzayo: Ngemva kokuhlanganisa, yenza ukuhlola okusebenzayo esibanjeni somnyango ukuze uqinisekise ukuthi ukuzungezisa, ukushintshwa nokunye ukusebenza kuhle futhi akukho ukuminyana.